Managing thermal heat in a ship depends on plate heat exchangers (PHEs), but their upkeep does not always reach the level of precision they require. Here at Sealong Marine, we’ve updated industry standards by using the latest equipment and accurate methods to detect faults and enhance the performance of any vehicle.

The Limits of Conventional Inspection Methods

With regular checks only, microscopic faults, broken gaskets and any plate-related issues usually go undetected. When small issues are ignored, they may result in leaks, waste more energy and cause serious failures. According to the studies, only 32% of the time are premature PHE replacement caused by more serious and challenging problems.

Sealong Marine’s way of working involves very precise steps.

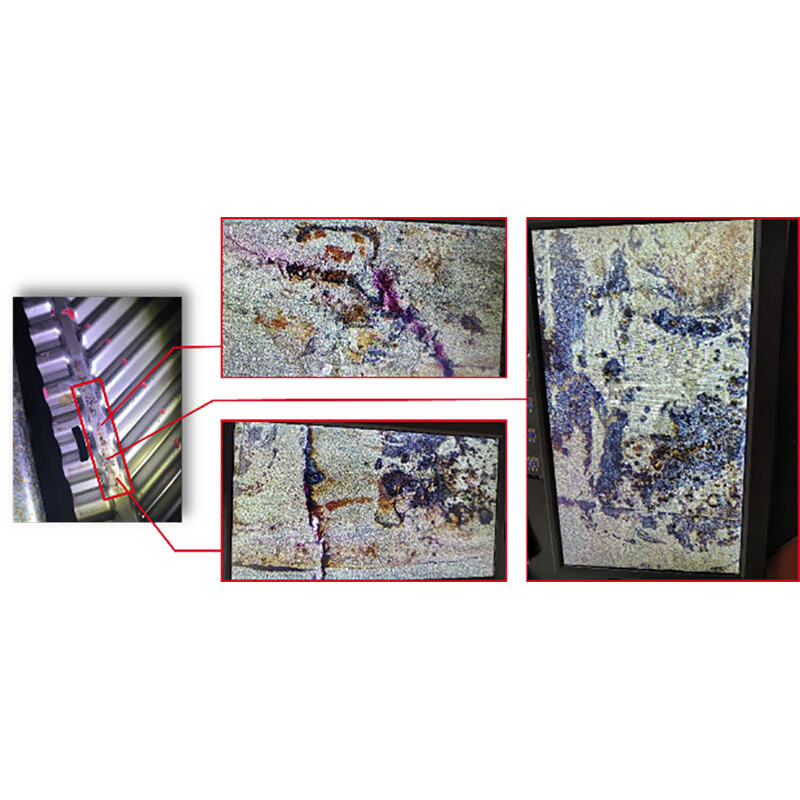

All our technicians in the USA use a predetermined four-step process. First, a series of electron microscope scans is performed to distinguish very tiny cracks and spots of corrosion that are not visible by sight. Following identification, gaskets are analyzed using spectrums to make sure the parts are strong enough to reuse. For the third phase, CIP procedures are used together with environmental-friendly solutions to wash biofilms out of the plates without harming them. Ultimately, testing at 1.5 times the operating pressure checks the strength, as AI algorithms ensure the stress is distributed properly.

Innovative Ways That Improve Reliability

Our service is distinguishable because we use a range of specialized tools. Evenly tightening bolts prevents the bolts from causing the plates to swap shape. When applying gaskets, we always choose 3M’s marine-grade adhesives since they are designed to resist temperature changes and work well with many chemicals. Using ultrasonic thickness gauges, these gadgets make maintenance much more precise.

Uncovering Hidden Threats, Delivering Guaranteed Results

Traditional tools usually ignore hazards such as rust in gaskets or fragile fractures from vibration; our tools always find them. In the past, 22% of checked units revealed defects on inspection that would have failed within six months. Taking care of these matters early saves on unexpected drydock costs of $120,000, as well as adding up to 7 more years to the life of the PHE.

We have Europe’s biggest PHE test rig which is able to emulate real conditions in the field. If a unit is serviced, it gets a health passport which records how it performed both before and after the maintenance. Let Sealong Marine be the one to ensure your equipment is cared for properly. Call us to arrange a precise inspection now, since unknown problems should not guide your company’s future.

EN

EN