পরিচিতি: মারিন সুরক্ষায় গুণবত্তাপূর্ণ এনোডের বিশেষ ভূমিকা

করোশন দ্বারা জাহাজের ধ্বংস মারitime জগতের বৃহত্তম হুমকি যা জাহাজের গঠনগত ব্যর্থতা ঘটায়, খরচবহুল রক্ষণাবেক্ষণের প্রয়োজন করে এবং চালু ক্ষমতা হ্রাস করে। ক্যাথোডিক প্রোটেকশনের মাধ্যমে জাহাজ চালাতে উচ্চ-গুণবত্তার জিন্স এবং অ্যালুমিনিয়াম এনোড প্রয়োজন যা বিভিন্ন সরবরাহকারী ভিন্নভাবে কাজ করে।

Sealong Marine Engineering (SME) বুঝতে পেরেছে যে এনোডের গুণবত্তা জাহাজের নিরাপত্তা এবং চালু জীবন ব্যাপি নির্ধারণ করে। আমাদের কোম্পানি ২০০০ সাল থেকে প্রতি বছর ১,০০০ টিরও বেশি জাহাজে উন্নত এনোড প্রদান করেছে। এনোডগুলি আমাদের নানতোং শহরের কারখানায় উৎপাদিত হয় যা ISO ৯০০১/১৪০০১/৪৫০০১ সার্টিফিকেশন মানদন্ড অনুসরণ করে।

এই গাইড তাত্ত্বিক এনোড সরবরাহকারী খুঁজে পাওয়ার উপায় এবং কেন SME তার পরিষ্কার উপাদান, সঠিক উৎপাদন প্রক্রিয়া এবং পণ্যের বৃদ্ধি প্রাপ্ত দৈর্ঘ্যকালের কারণে বাজারে অগ্রগামী তা দেখায়।

প্রধান উপাদান যখন নির্বাচন একটি এনোড সাপ্লাইয়ার একটি এনোড সাপ্লাইয়ার

১. মatrial গুণবত্তা: শুদ্ধ জিন্স বি. কম গুণের বিকল্প

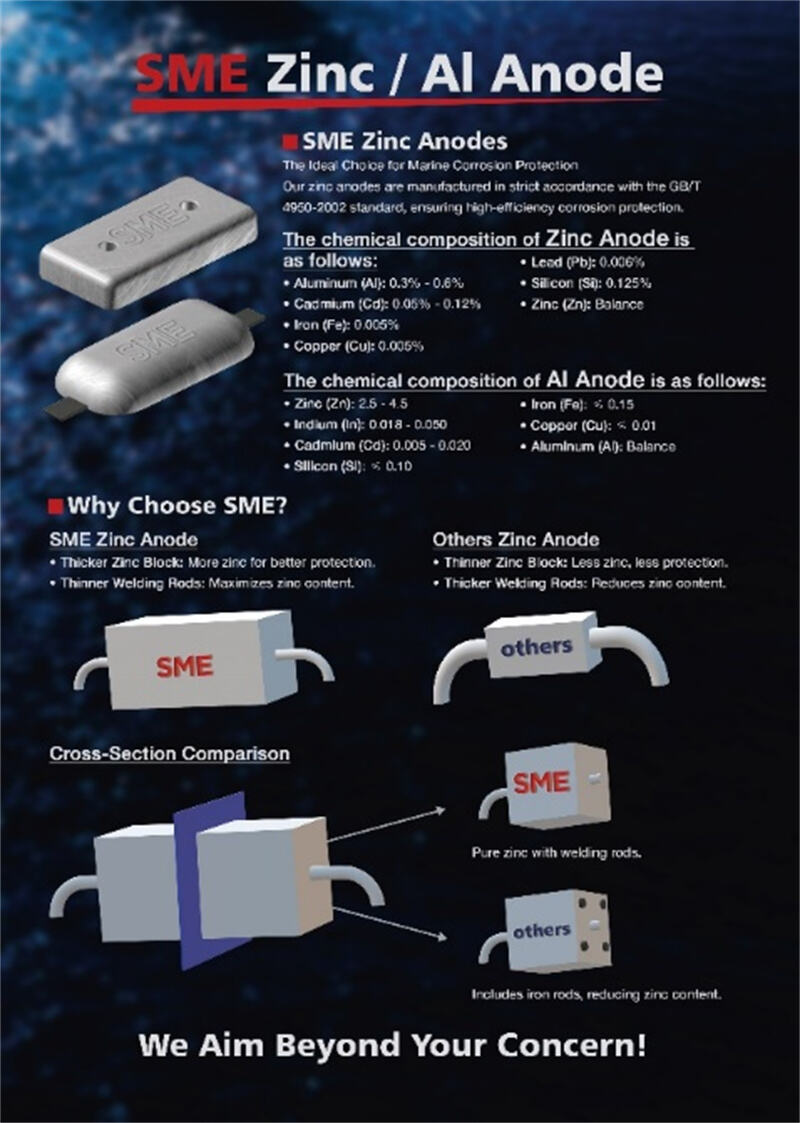

✔ SME Anodes : এসমিই থেকে পাওয়া ধাতব অ্যানোডগুলি GB/T 4950-2002 মান অনুযায়ী তার নির্মাণ এবং ৯৯.৯৯৫% বেশি শুদ্ধতার জিংক উৎপাদনের মাধ্যমে সর্বোত্তম সুরক্ষা প্রদান করে।

✔ অন্যান্য সাপ্লাইয়ার : অন্যান্য কোম্পানিগুলি যে জিংক পণ্য সরবরাহ করে, তাতে লৌহ ছোটা সহ বিলুপ্ত গুণবত্তার উপাদান রয়েছে যা উৎপাদনের জীবনকাল এবং সুরক্ষা কার্যকারিতা হ্রাস করে।

✔ ক্রস-সেকশন তুলনা :

SME : এসমিই অ্যানোডের কেন্দ্রে শুদ্ধ জিংক উপাদান রয়েছে এবং গঠনগত আঁকড়া তার এককতা রক্ষা করে।

অন্যান্য : অভ্যন্তরীণ লৌহ উপাদানের উপস্থিতি জিংকের পরিমাণ হ্রাস করে এবং এই ডিভাইসের জন্য সুরক্ষা কার্যকারিতা হ্রাস করে।

2.প্রোডিউস অংশ মানদণ্ড: সনাক্তকরণ প্রাপ্ত এবং সমতুল্য উৎপাদন

✔ SME : আন্তর্জাতিক মানদণ্ড (ASTM, MIL-DTL, DNV-GL) অনুসরণ।

✔অন্যান্য : পণ্যগুলি সঠিক সনাক্তকরণ প্রদর্শন করে না এবং তাই অনিশ্চিত মানের হয়।

3.ইনস্টলেশন ন বিশেষজ্ঞতা: সঠিক ফিটিং এবং দীর্ঘ জীবন

✔ SME : এসমিই বিভিন্ন হাল ধরনের সাথে মেলে যাওয়ার জন্য বিশেষ এনোড ডিজাইন সমাধান প্রদান করে বাজার।

✔অন্যান্য : সাধারণ আকৃতির ধরনগুলো তাদের অনিয়মিত আকৃতির কারণে সাধারণত নিরাপদ আটকানো স্থাপন করতে পারে না, ফলে করোজন রক্ষণাবেক্ষণে অস্থিতিশীলতা তৈরি হয়।

৪. পরবর্তী বিক্রয় সহায়তা: নির্ভরযোগ্য রক্ষণাবেক্ষণ এবং মনিটরিং

✔ SME : কৃত্রিম বুদ্ধি (AI) দ্বারা চালিত করোমশন নিরীক্ষণ এবং পূর্বাভাসিত প্রতিস্থাপন স্কেজুল প্রদান করে।

✔ অন্যান্য : অন্যান্য উৎস থেকে প্রদত্ত সীমিত তেকনিক্যাল সাপোর্ট গোপন অ্যানোড খালি হওয়ার ঝুঁকি বহন করে।

কেন নির্বাচন করবেন এস ME’s সিঙ্ক এবং আলুমিনিয়াম অ্যানোডস?

✅ উত্তম মেটাল শোধতা-কোন লোহা দূষণ নেই, যা দীর্ঘস্থায়ী নিরাপত্তা নিশ্চিত করে।

✅সার্টিফাইড ম্যানুফ্যাকচারিং-GB/T 4950-2002, ASTM এবং DNV মানদণ্ডের সাথে মিলিত।

✅ কাস্টম সমাধান - বিশেষ জাহাজের প্রয়োজনের জন্য অ্যানোড।

✅ স্মার্ট মনিটরিং-সময়ের জন্য AI-ভিত্তিক ট্র্যাকিং দ্বারা অপটিমাল প্রতিস্থাপন।

✅ গ্লোবাল সাপ্লাই চেইন - বিশ্বব্যাপী শিপইয়ার্ডে দ্রুত ডেলিভারি।

অনুমান অন: আপনার হুলকে সঠিক এনোড সাপ্লাইয়ারের সাহায্যে রক্ষা করুন

গুণহীন এনোড বাছাই করলে দ্রুত জোঁক, উচ্চ রক্ষণাবেক্ষণ খরচ এবং নিরাপত্তা ঝুঁকি আসতে পারে। SME গ্যারান্টি:

✔ বেশি কার্যকারিতা জন্য প্রিমিয়াম জিন্স/আলুমিনিয়াম অ্যালোই

✔ সার্টিফাইড উৎপাদন প্রক্রিয়া

✔ বিশেষজ্ঞ স্থাপনা পরামর্শ

✔ ২৪/৭ তেকনিক্যাল সহায়তা

আজই SME-এর সাথে যোগাযোগ করুন উচ্চ-পারফরমেন্স এনোডের জন্য যা জাহাজের জীবন বাড়িয়ে দেয় এবং খরচ কমায়!

EN

EN