Kynning

Varmstjórnunarkerfið á skipinu þínu er birt af varmuleiðréttingaraflaíslum sem grunnvörumerkið við Sealong Marine Engineering (SME). Ræddum starfsemi síðan 2000 og nú þjónum við sem virk marínumverkfræðifélag með yfir 100 mjög vískileg stafræði sem keyra 5,000 ferningsmetra nútíma verkstæði í Nantong City. Þjónusturnar okkar, sem eru skilgreindar með ISO 9001/14001/45001, styrka yfir 1,000 skip á ársbasi til að halda og endurskilja skip efni.

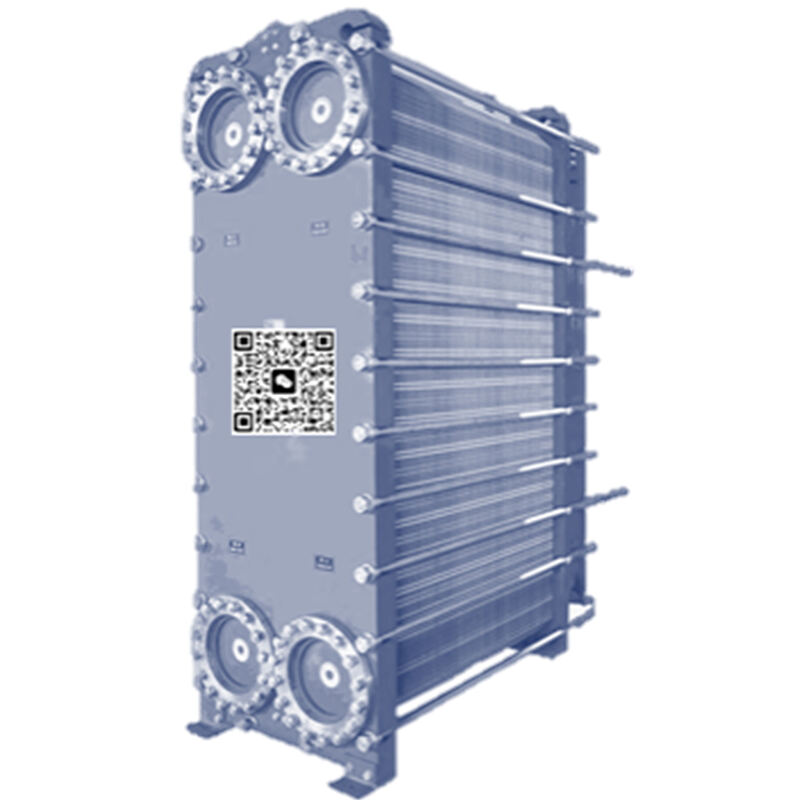

Þjónustu fyrir värmiþvottara með flatvarmaveislum

Besta stöð fyrir venjulega þvottuþjónustu

Vors skipulag fyrir þvottu:

Hátryggt vatn

Náttúrlegur kemiþvottuloysir

Hrafnavskurðarbakki fyrir hrauðmótt hluti

Sjálfvirk vskurðaraðgerð gefur sömu niðurstöður í hverri keyrslu.

Þros og athugun að borði

Vor færraþjónustuferli bjóða:

Heildarsamsetning og aftenging platarpakkanna

Nákvæmr sjónar- og mælingaraðferðastrengur

Óskaparefni-prófanir (NDT) aðferðir

Prófið inniféllur rannsóknar á rífningssamsetningu og uppskizingu á brúunarmynstum.

Allt-að-virkja viðhaldsþjónustu með 12 mánaða tryggingu

Viðhaldspakkinn okkar inniféllur:

Allar læður eru skiptar út fyrir OEM-gerð materiali.

Skipt á plötum aftur og aftur

Framkvæmd próf og tilpasun

Industry-Agni 12 mánaða yfirferðargári

Fagmennska vatnastiggtæki

Við notum:

Tölvaþjónn hýdralískra strammkerfis

Nákvæm mælingaraðgerðir á dreifingarstuðlar

Sjálfvirk forritun á strammingarröð

Kraftsjákvæðarkerfi

Hydro-Water Reningaraðstæði

Vor frumvarpandi reningsþegar eru eftirfarandi:

Umboðarhljóð (500-1,500 Sai)

360 ° fyrir fulla dekningu

Gjaldmiðlar kerf til vatnsskyklingar

Þættirkerfið virkar með sjálfvirkar eftirlitaskipti sem hafa kröfu eftirlitsmöguleika.

Trykjasóknargangur fyrir gæðagervi

Þær strengjar prófunarglæpur okkar eru:

Hýdrostætt-próf á 1,5x vinnuþrysti

Prófamátið fyrir sterkleika gúmsins notar trykjákvæðun.

Hitnaðarhringspróf

Tölfræðilegir þrýstingaskráningar og skýrslur

Innfarið 3M líma

Við notum einungis:

3m ™ merkislíma fyrir gasket

Háhitustandfærr yoga

Sjávargráðu rústværnarvörn

Samþykkt aðferð til viðbótar

Sérsniðin stálgrunnarinn fyrir geymslu og flutning

Tækifæri okkar sérhluta innihalda:

Þungskipulagð stálþætti

Klifavarmt umhverfi

Rásleiðunarkerfi

RFID-sporingaraðilar

Rafeindarmikroskop fyrir athuga

Þær frumvarp ákvörðunar aðgerðir okkar þátta:

5000x stækkingarfulltrúa

Análysi yfirborðsþrautars

Samsetninguafgangur af mælitólum

Útkannslu af mikro-splatu

SME PCIM (Vatnskælingarstjórnun) Kerfi

SME PCIM (Vatnskælingarstjórnun) Kerfi

Tenging QR kóða

Býr til vörum spárlaus fylgjarskrá kerfi:

Einkenni QR kóða fyrir hvern einingu

Aðgangur að þjónustuauðkenni á skýi

Hrað útreikningur þjónustufræða

Vafri-væn skilaboð

WMS Module

Gagnagrunnur okkar fyrir vörulagerstjórnun:

Rauntíma-fylgjetill á hlutum

Sjálfvirkt útreikningur endurskráningararpunkts

Samþætting staðfestingar söluaðila

Greining afbrýnandi mønstera

Tímarit í rauntíma

Rannsóknarforritið okkar vistar:

Uppfærsla á staðu verks í raun

Sjálfvirk vísing á framkvæmd

Viðbótareinkunn fyrir skýrslur

Þekking á skeiðum frá fornöfnum

PMS-þátta

Eiginleikar kerfis okkar fyrir verkefnastjórnun:

Samræmdur Gantt-kartagerð

Bestun á viðskiptavinatöku

Sjálfvirk fylgjandi á merkistöðum

Samþætt skjalastjórnun

Ályktun

SME býður upp á fullkomið lausnir fyrir värmiþvælingarplötur sem sameina nútíma eftirlitsmáta fysískra afgreiðslu með fremst á milli digitala stjórnunarferla. Lengi starfshæfileiki okkar um 20+ ár samtals, og ISO-sertefækð rannsóknir við sömu tíma og nýsköpuð aðgerðir verður að skemma skipin þín frá hávarmi sprettingum og lágstukeyptu keyrsluatriðum. Þú getur hafðast við teami okkar núna til að fjalla um vörumerkingarsamninga fyrir värmiþvælingarkerfi.

Efnisyfirlit

- Kynning

-

Þjónustu fyrir värmiþvottara með flatvarmaveislum

- Besta stöð fyrir venjulega þvottuþjónustu

- Þros og athugun að borði

- Allt-að-virkja viðhaldsþjónustu með 12 mánaða tryggingu

- Fagmennska vatnastiggtæki

- Hydro-Water Reningaraðstæði

- Trykjasóknargangur fyrir gæðagervi

- Innfarið 3M líma

- Sérsniðin stálgrunnarinn fyrir geymslu og flutning

- Rafeindarmikroskop fyrir athuga

- SME PCIM (Vatnskælingarstjórnun) Kerfi

- Ályktun

EN

EN